UF Technology Explained

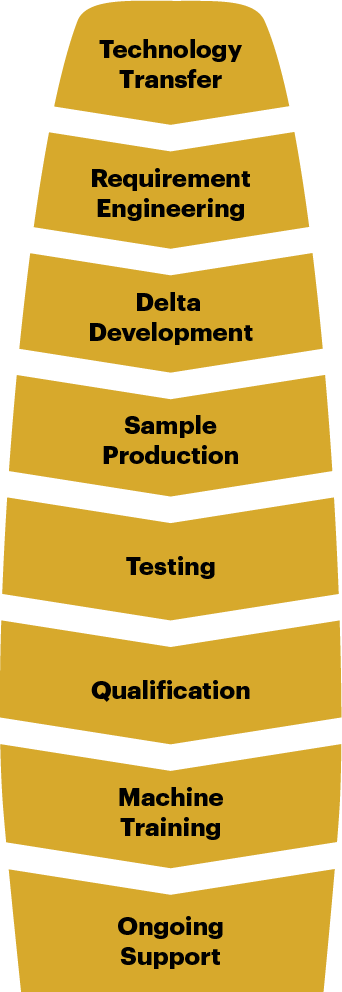

ULTIMATE FRAGMENT is an unprecedented and pioneering possibility for a technology transfer to your domestic entities.

ULTIMATE FRAGMENT is an end-to-end package including individualization to a specific target scenario, production facility setup, testing and qualification services as well as an ongoing support for UF production machines.

Thus, the technology comprises MORE THAN JUST THE PRODUCT.

The innovative modular approach of the UF product series caters for a wide range of adjustment points for an individualized product – starting from various fragment disc designs and individually selectable explosives to the ability to remove the explosive completely (e.g., for a separate storage/shipping).

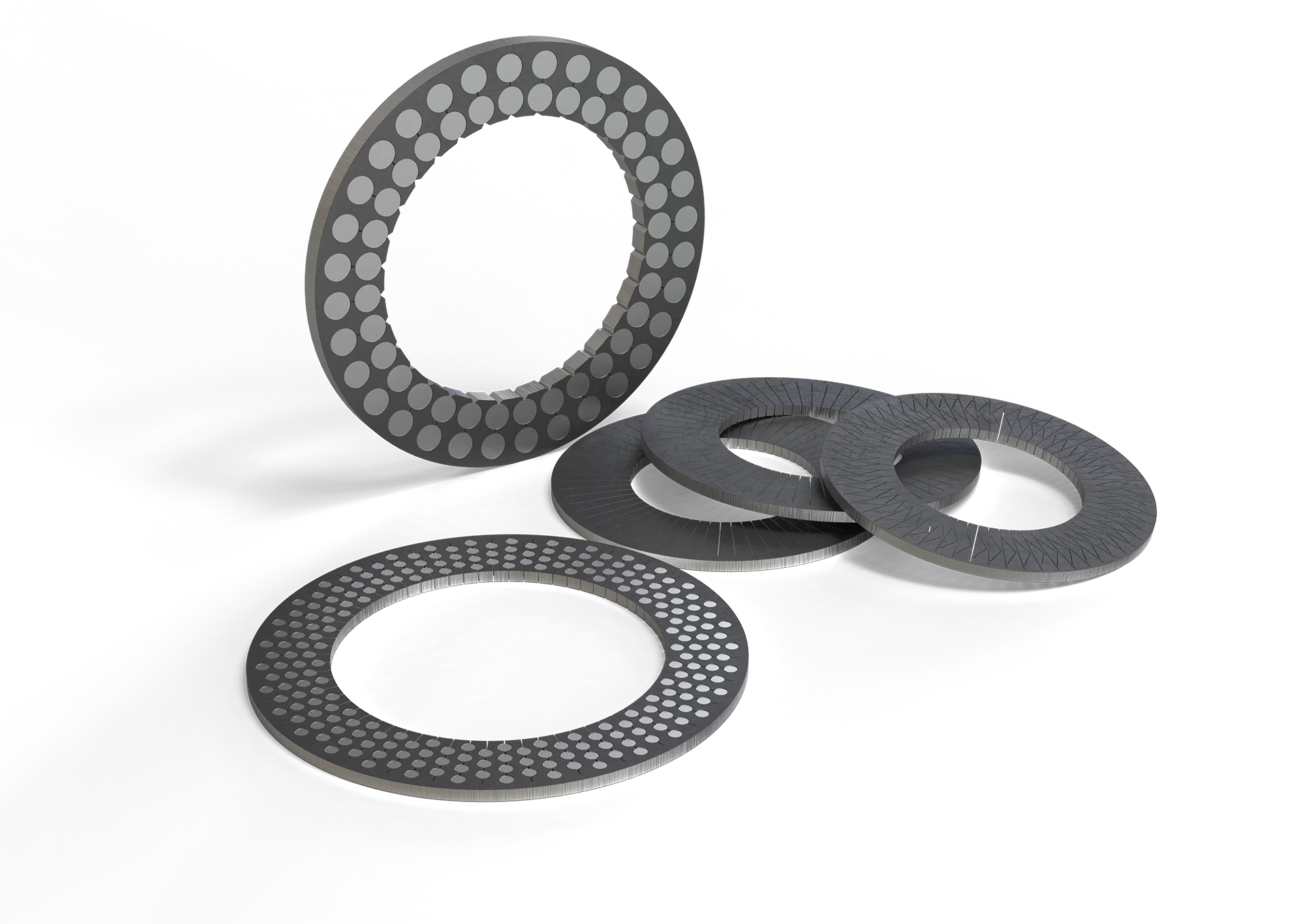

UF Fragment Discs

Customizable splinter discs, which could be further upgraded by tungsten or other heavy metal cylinders, allow for a flexible adaptation of the fragment mass. This can be done for every target scenario separately, completely fitted to the customer’s requirements.

UF Fragment Discs are optimized for various target scenarios, including dismounted infantry, infantry, protected infantry, vehicles, hardened vehicles, drone defense, and APC/IFV.

UF Explosive Capsule

UF Explosive Capsules are available as an additional module, which transforms the necessity of casting explosives to an obsolete approach. The new explosive capsules further facilitate an ad-hoc exchange of explosives to adapt to changing requirements (e.g., insensitive munition).

Thus, ULTIMATE FRAGMENT bodies can be disassembled once the explosive reaches its end of life to simply replace the old explosive cartridge by a new one. By that, less disposal costs arise as the rounds enter a circular, extendable lifecycle. Additionally, the separated storage of explosives and metal bodies decreases storing and shipping costs as special safety requirements only apply to a fraction of the storage/shipping volume.

UF Fusion Technology

Since no forging infrastructure is required, the production facility itself is as modular as the product. Each component can be subject to a make-or-buy decision to enable an easily scalable production that is efficient already in lower output quantities. Even in a complete in-house production, the ULTIMATE FRAGMENT technology – except for the core fusion technology – can be produced with standard production machinery.

The combination of a sole requirement for standard machinery and the possibility to outsource the production of individual components further cater for a space saving plant that even qualifies for an uncomplicated relocation for geo-strategical reasons.

Flexibility is a stringent factor in the ULTIMATE FRAGMENT production setup. Depending on the current infrastructure, existing machines can seamlessly be integrated if they fulfil minimum requirements. The possibility to automate substantial parts of the production further assists in the maximization of production efficiency.

Further, one production setup is capable of producing a wide range of various warheads.

UF caught your interest?

Frequently Asked Questions

What is Ultimate Fragment?

ULTIMATE FRAGMENT is an innovative European technology and stands in equal measure for a radically new approach of shell production and convincing improvements in fragment efficiency. Ranging from Caliber 40 upwards, ULTIMATE FRAGMENT describes a series of products which all share a new, forge-free approach to shell production, and thus are able to inherit specific customer requirements based on their target scenarios.

How can I adopt Ultimate Fragment?

ULTIMATE FRAGMENT can be purchased as final products like common standard shells.

However, ULTIMATE FRAGMENT further offers you the possibility to adopt the whole technology in order to run an independent, self-hosted, and domestic production.

Who is eligible to obtain ULTIMATE FRAGMENT?

Ultimate Fragment can be purchased by official authorities and private companies who are able to provide a valid EUC. Further, holding national licenses is a prerequisite to purchase both ULTIMATE FRAGMENT technology and products.

What makes ULTIMATE FRAGMENT unique?

Long-established, highly unflexible production methods impede traditional shell vendors from responding to individual customer needs. Since the ULTIMATE FRAGMENT production is waiving forging technologies completely, obsolete boundaries are overcome. Thus, ULTIMATE FRAGMENT allows for tightly synchronized changes of the production program and quantity at no additional effort.

We are proud to offer not only our products, but our technology for a completely independent, domestic production in the customer’s home country. The flexibility of ULTIMATE FRAGMENT even allows to distribute a production premise to various locations and thus keeping repercussions from a potential damage of one site at a minimum.

What makes ULTIMATE FRAGMENT cost beneficial?

Compared to currently available rounds, ULTIMATE FRAGMENT increases cost efficiency by a series of factors; From an isolated perspective, the possibility to produce various calibers with one production setup already adds to a cost benefit. A lifecycle perspective further underlines this benefit as explosives can be removed from the shell body at any time, which extends re-usability of shells, diminishes disposal costs and widens the application potentials for stored shells.

Is ULTIMATE FRAGMENT already an approved technology?

Both static detonation tests as well as live firing tests have been successfully completed.

Is a complete transfer of technology possible?

Yes – ULTIMATE FRAGMENT can be completely adopted for independent shell productions.